After our Meeting with Barbara last week in Rhodes, we are finally at completion of the paperwork. Barbara was so helpful during this process. Her knowledge and quick communication was simply incredible, and we were really impressed. Barbara has had many years experience in the electrical industry, has previously worked for Clipsal, and has an electrician for a husband!

The way the appointment ran was great. It lasted for roughly 3 hours, and was presented in a way that was clear, concise and easy to follow. Barbara's laptop was connected to a wall-mounted LCD screen so that our electrical plans were visible to us, and we could actually see changes that were made in real time. We were also able to look at all of the choices available to us, in terms of switches, fittings etc.

We had very good inclusions within the tender and also the standards within the Rawson build to start with.

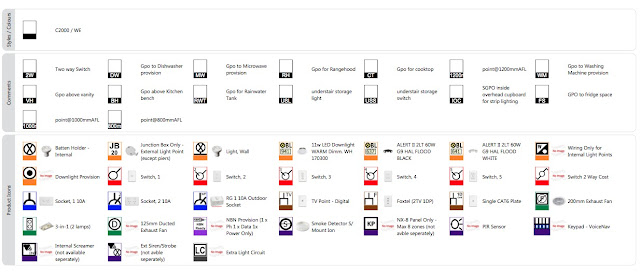

12x 11W LED downlights and the 'Lux' standard inclusions.

Lets start with the standard plan. What do you get?

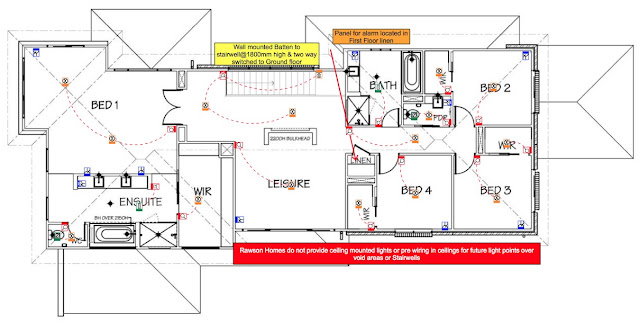

Now the final plans. This is what we ended up with after the meeting and email conversations.

You may have to come back and have another look after reading ;)

Firstly, the additional points on this plan are;

5 x 10A 2 Socket GPOs

1x Digital TV Point

1x Foxtel Pre-wire

5x Category 6 Data points

3x Wiring only for light points

19x Downlight provisions (plug-base in the ceiling)

3x Flood lights (upgrades on external J-boxes)

As the house is a two storey, there is only one chance to fitout the ground level for lighting, power and data. At least 90% of the extra costs are incurred here. Barbara advised us that she has seen many clients attempt to complete electrical work on the lower level post handover, and it has usually turned into a nightmare.

You will also see a strange mix of battens and downlight provisions, which is all due to the handover 'Occupation Certificate'. You must have at least one light in each room.

Data points are provided in the Leisure, Study, Dining (on ceiling), Family, and upstairs hallway (on celing). I will be using corporate grade wireless equipment that is available to me through work. The Access Points will be mounted on the ceiling to maximise decent WiFi throughout the house. The units are small minimalist white boxes, featuring internal aerials and small activity lights.

Lucky for us, we have an electrician in the family for post-handover fitout of the additional lighting. This will be easier on the pocket upstairs and also means we will have access to 'trade supply pricing' for LED lighting throughout the home.

Upstairs is pretty standard. We have mainly placed lights in the bedrooms so that extra LED downlights can be simply retro-fitted post handover, and no hole patching will be necessary.

Extra lighting circuits in the ensuite were necessary as the nib wall doesn't run up to the ceiling. Another win here was that we had the cavity door moved in the WIR so that we had a wall section adjacent to the ensuite shower to provide more space for a towel rail, which was previously lacking. This will have a heated towel rail which will be installed after handover.

** This was a fortunate opportunity as we hadn't yet signed the internal

selections. Otherwise a drafting charge would have followed. I can't help but think this is a common pitfall that project builders bank on.

Also, with all these extra lights we had to pay for an additional 10A circuit on the switchboard!

Finally, there are some small luxuries hidden in the plan, which you may, or may not have noticed:

1) A power point installed in the kitchen cabinet (also switched on the kitchen wall switch) for under cupboard/over bench LED strip lighting.

The overhead cabinets will be mounted on 20 mm which will create a neat / hidden reveal to hide the LED strip.

** Another fortunate change due to unsigned interior selection paperwork

2) Multiple areas using two-way switching: in entry hallway, stairs, spot lighting in Laundry/Garage, upstairs hallway. The convenience of two-way switching can't be beaten. The only standard here for Rawson is for the stairs. All others are variations to standard.

3) Master Bedroom bedside pendant light provisions. ie extra wiring in the ceiling and light switches on the nib wall behind the bed. His and Hers switched lights.